What Is Hardline

HARDLINE AND COAXIAL PREMISES CABLING

What Is Hardline Coaxial Cable?

Hardline is the solid aluminum cable used for long distances, usually between 300-400 feet. It is often attached to telephone poles or trenched underground. Hardline cable is very moisture resistant and has very low impedance characteristics.

If you have some sort of big facility built before about 2000 you probably have hardline cable in it. Hardline cable is manufactured similarly to, but does not look like regular coaxial cable. It is approximately 1.75 inches thick! It can carry hundreds of channels of cable television, thousands of phone calls, or enough bandwidth ability for a medium sized office building. It was your only choice back then, and until about 2005 it was still very commonly used in residential and commercial cable plant installations.

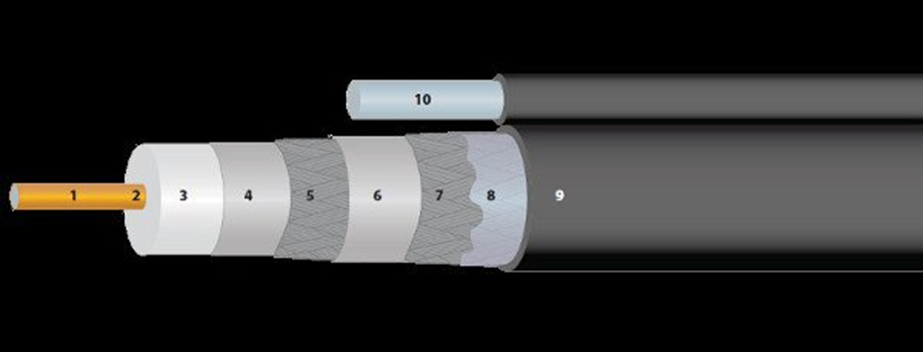

Coaxial cable is a type of cable that has an inner conductor, surrounded by a layer of insulation, and covered with a conductive shielding. Almost all coax cable also has an insulating outer jacket. The diagram below illustrates the construction of a typical cable. Electrical signal flows through the center conductor. To be further specific, most of the power flows in the middle of the center conductor and signal flows on the outer surface of the center conductor. This makes it crucial to fabricate perfect connectors and splices.

Hardline cable was mainly used for long trunk runs, and then would split off to (in a common cable plant) RG6 or RG11 cable risers and feeds so it could get where it needed to go. If you think it’s hard to work with RG6, working with hardline cable is extremely difficult. It’s heavy, and practically impossible to bend. It takes gigantic tools just to put a connector on. Hardline cable, connectors, splitters, taps, couplers, and amplifiers are readily available today, as well as the tools that you will need. Solid Signal has a lot of hardline related products available, but they are all special order items. It’s just not something in common use today because it is so much easier and less expensive to work with fiber. You can find most of the required tools at www.giganetpro.com and technical assistance at www.supertechpro.com .

Hardline components comprise some of the most important pieces to delivering service within many subscriber home networks, so making sure the connectors and cables are prepped and installed properly is crucial to network performance.

Hard line coaxial cable makes use of a center conductor that is built out of materials such as copper, silver, aluminum, or steel and this type of cable is usually larger in circumference than other forms of coaxial cable. These types of cables may be used in high-strength signal transmission. Some forms of hard line make use of pressurized nitrogen to prevent moisture intrusion, as well as to prevent arcing.

Hardline cable is used from the headend through the trunk and feeder lines, to the home or end user location. There are many different connections used within a cable plant, including but not limited to amplifiers, line extenders, and multitaps.

If even one connector is not installed properly, it is a source of possible failure and can very much impact performance of the whole network.

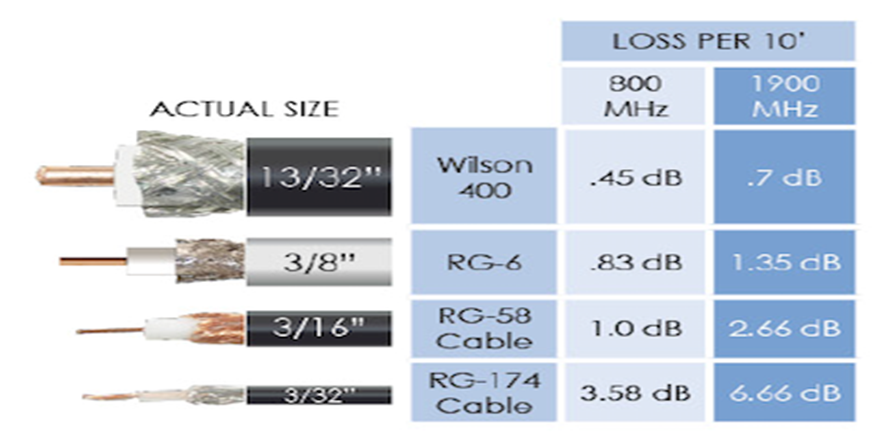

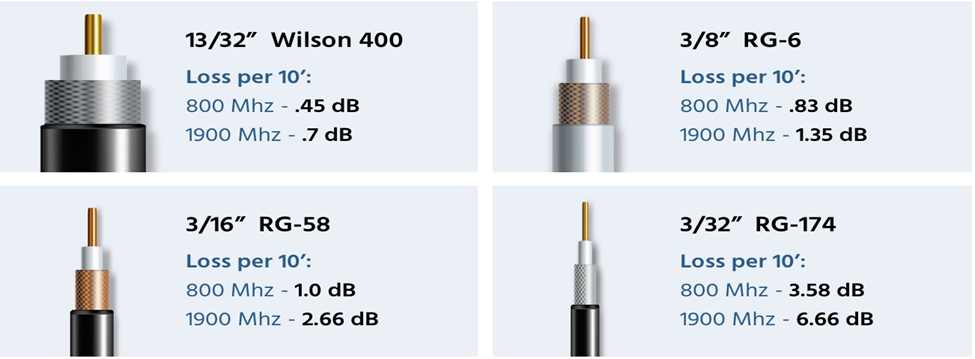

The three most commonly used coaxial cable types for video applications are RG59/U, RG6/U, and RG11/U. RG59 is usually used for very short jumpers, with RG6 favored as the standard. Both are available with either a solid copper or copper covered steel center conductor. It’s good for basic analog television (devices that receive television and radio signals) service applications and for basic CCTV security camera systems utilizing shorter cable runs. 400 and 500 cable is generally found in cellular booster and distributed antenna systems.

Uses of coaxial hardline cables

In home and small offices, shorter run coaxial cable types are used for cable television, home video equipment, inexpensive, lower quality radio equipment, and measuring devices. In the past, coaxial cables were also used as an early form of Ethernet which supported speeds of up to 10 Mbps. Most of the aforementioned use cases have been replaced by the use of twisted pair cabling. However, they remain widely in use for cable broadband internet. Coaxial cables are also used in cars, aircraft, military, medical equipment, as well as to connect satellite dishes, radio, and television receivers.

PARTS OF A COAXIAL CABLE

Center conductor – copper-clad steel. (solid copper is preferred for satellite applications and more than 50 feet)

- Center conductor bond – clean stripping polymer is utilized to block moisture migration.

- Dielectric – polyethylene providing mechanically stable, closed cell foam.

- First outer conductor – shield with an aluminum-polymer aluminum tape securely bonded to the dielectric core.

- Second outer conductor – an additional aluminum polymer tape is used in tri-shield and quad-shield constructions to further enhance high frequency shield isolation before and after flexure.

- Third outer conductor – an additional aluminum polymer tape is used in tri-shield and quad-shield constructions to further enhance HF shield isolation before and after flexure.

- Fourth outer conductor – an additional 34 or 36 AWG aluminum braid is used in quad-shield constructions to further improve low frequency shield isolation in extreme RF noise environments.

- Corrosion resistant protectant

- Indoor and aerial – a non-drip material designed to eliminate moisture migration into the cable construction.

- Underground – a flowing compound able to seal small jacket ruptures.

- Jacket – a ultraviolet resistant outer jacket of either polyethylene (PE) or flame resistant polyvinyl chloride (PVC) is available to protect the core during installation and during the installed life of the cable.

- Integral messenger – a galvanized, carbon steel wire support member attached to the cable by a separable web. The messenger is used for pulling tensile strength and to further support aerial applications.

How Coaxial Cable Works

- A center conductor that is usually made from copper. This conductor transmits video and data.

- Surrounding the center conductor is a plastic dielectric insulator. This prevents signal loss and helps the reduction of EMI (electromagnetic interference). It also provides insulation and creates distance between the core conductor and external layers.

- A copper braided mesh shields the cable from EMI and radio transmissions.

- The plastic external jacketing prevents damage to the internal layers.

Coax Cable Types and Their Uses

1. Hard-Line Coaxial Cable

The most commonly used type of coaxial cable, hardline coaxial cables are preferred in applications that require a high signal strength. These cables usually measure around 0.5 inches to 1.75 in thickness, which makes them larger in circumference than other coaxial cable types. They have a center conductor made of materials like silver, copper, aluminum, or steel. Some hardline cables utilize pressurized nitrogen for moisture prevention and to prevent arcing. Hardline coaxial cables are usually used in the transmission of CATV. One of these cables has the bandwidth capabilty to transmit hundreds of cable television channels. More than that, they are also used as telephone and internet lines. If your office or apartment building is fairly medium sized, a hardline coaxial cable can be depended upon to do the job of delivering internet and telephone connectivity.

2. RG-6 Coaxial Cable

RG-6 is another coaxial cable that is widely found in our area and in most of the world. The “RG” in its name stands for “radio guide,” while the number refers to the cable circumference. (the distance or line from one edge, through its center, to the other edge). In this case, the “6” points to/shows that the cable has a (distance or line from one edge of something, through its center, to the other edge) of .06 inches. RG-6 cables are also called RF (radio frequency) cables. One of the reasons the RG-6 is so popular is because it tends to have larger conductors. This helps improve signal quality because they have better shielding and thicker dielectric insulation. Larger circumference cables are better able to handle higher frequency level signals. What’s more, some RG-6 cables contain waterproof gel and can be direct buried. Because of its flexibility, RG-6 is easier to install in ceilings and walls. That’s what makes this cable ideal for transmitting cable television and broadband internet, and also the reason why they are so commonly found in residential homes. The RG-6 is the perfect cable to use in entertainment systems for both residential and commercial applications.

3. RG-11 Coaxial Cable

Almost the same as RG-6, RG-11 is a cable that has a 75-ohm impedance. It is thicker than RG-6, and is used most commonly for application needs found in satellite, television, and cable systems. Although it is less flexible than RG-6, it provides the benefits of lower loss and greater distances at a reasonable increase in price.

4. RG-59 Coaxial Cable

Almost the same as the RG-6, RG-59 is found in many domestic video applications. It’s seen as a (compared to other RG classifications) thinner center conductor, which allows it to be manufactured with less metal and waste for low frequency transmissions and short cable runs.

5. Tri-axial Cable

The tri-axial coaxial cable (also called “Triax”) is seen as an added shield in the form of a copper braid. Because this braid is grounded, it protects the cable’s inner conductive elements from capacitive field noise and ground loop currents.

What’s more, since the triaxial cable offers higher radio frequency ability and interference rejection, it’s ideal for use where strong (related to electricity producing magnetic fields) signals might cause interference.

More than that, triax reduces cable loading and cable losses. The most commonly seen use of triaxial cable is in cable television systems. It is also commonly used to connect cameras to a CCU (camera control unit).

DIFFERENT TYPES OF RG CABLE & SIZES OF COAX CABLE

Reference Source: https://www.supertechpro.com ,thomasnet.com, ppc-online.com, commscope.com, thejonspencerbluesexplosion.com, https://www.giganetpro.com/

SuperTech is FCC certified and can provide Consultation Services, as well as affordable premise cabling solutions for your Commercial Business applications.